Products

-

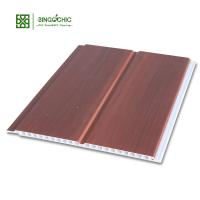

Lamination PVC Panel 200mm CTM2-6

-

Lamination PVC Panel 200mm CTM2-6

-

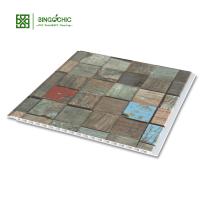

Lamination PVC Panel 200mm CTM2-5

-

Lamination PVC Panel 200mm CTM2-5

-

Lamination PVC Panel 200mm CTM2-5

-

Lamination PVC Panel 200mm CTM2-5

-

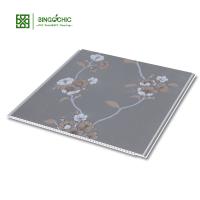

Lamination PVC Panel 250mm CTM3-1

-

Lamination PVC Panel 250mm CTM3-1

-

Lamination PVC Panel 250mm CTM3-15

-

Lamination PVC Panel 250mm CTM3-16

-

Lamination PVC Panel 250mm CTM3-20

-

Lamination PVC Panel 250mm CTM3-20

Interior PVC panels are specifically designed for interior decoration and ceiling finishes. Polyvinyl chloride (PVC) is a lightweight, corrosion-resistant, and waterproof material, making it ideal for use in kitchens, bathrooms, and other humid environments.

These panels typically feature a hollow-core design, reducing weight while enhancing structural integrity. Their surfaces come in woodgrain, stone-textured, or solid-color finishes, offering both aesthetic appeal and easy coordination with interior styles. Compared to traditional wall materials, PVC panels are quick to install—we offer either click lock or adhesive mounting options to shorten your construction timeline. Maintenance is equally straightforward—wipe with a damp cloth to prevent mold growth or discoloration.

Why We Choose PVC Materials to Produce Panels?

The construction and renovation industry has consistently demanded lightweight materials that are waterproof, moisture-resistant, and corrosion-resistant. Particularly in high-humidity environments like kitchens, bathrooms, and basements, traditional wood and stone are prone to mold, warping, or cracking, leading to high maintenance costs and short service life. Manufacturers like us began exploring alternative materials. During performance evaluations of various materials, we found PVC to excel in testing.

For manufacturers like us

PVC raw materials are relatively cheaper than wood, stone, or metal sheets. During production, processes like extrusion molding enable efficient batch manufacturing with controllable costs. PVC sheets are lightweight yet structurally stable, facilitating transportation and installation while reducing labor costs. PVC material readily achieves diverse aesthetic finishes through extrusion molding, surface printing, lamination, or coating—such as wood grain, stone texture, or solid-color panels—meeting varied customer and market preferences. This flexibility enables rapid new product launches and adaptation to shifting market trends.

For consumers

PVC's waterproof, moisture-resistant, and corrosion-resistant properties ensure long-term durability in humid environments without mold growth, warping, or cracking, significantly extending product lifespan. Additionally, PVC panels require minimal maintenance—no periodic painting or special upkeep is needed during use—further reducing upkeep costs. Today's consumers and interior design markets increasingly prioritize environmental sustainability, demanding higher standards from materials. PVC can be formulated with low-VOC (Volatile Organic Compounds) recipes, featuring smooth surfaces that are easy to clean—fully aligning with green renovation principles. Low-VOC PVC panels contain no harmful volatile substances, minimizing impact on indoor air quality. Compared to traditional wood or stone, consumers gain a healthier, more eco-friendly indoor environment.

Generally, PVC panels represent a mutual selection process among manufacturers, consumers, and the market.