Lamination PVC panels are revolutionizing modern construction and interior design. Their versatility, durability, and cost-effectiveness make them a popular choice for a variety of applications—from sleek interior decorations to robust commercial spaces, and even some outdoor settings. This article explores what lamination PVC panels are, the types available, their primary uses, material advantages, and maintenance guidelines, providing you with a comprehensive understanding of this innovative material.

What Are Lamination PVC Panels?

Lamination PVC panels are composite building materials crafted from polyvinyl chloride (PVC) with a laminated finish. Typically, these panels consist of multiple layers, including a decorative surface layer, a core material that provides stability, and sometimes an additional protective layer to enhance durability. This layered construction allows for a blend of aesthetics and performance, making them ideal for areas where appearance, moisture resistance, and ease of maintenance are paramount.

The manufacturing process involves high-pressure lamination and precise cutting, ensuring that each panel is both uniform in quality and designed to meet specific building standards. This technology results in panels that are lightweight, yet strong and capable of withstanding various environmental factors.

Types Available on the Market

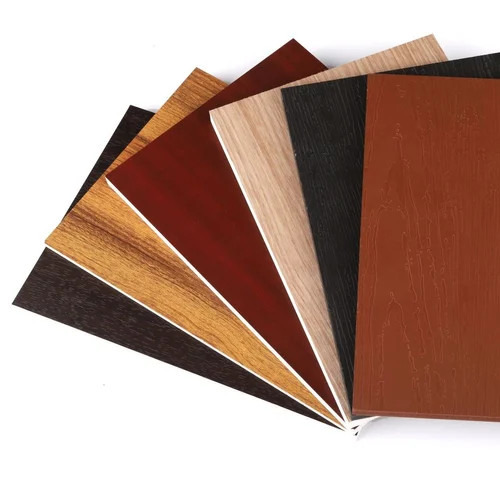

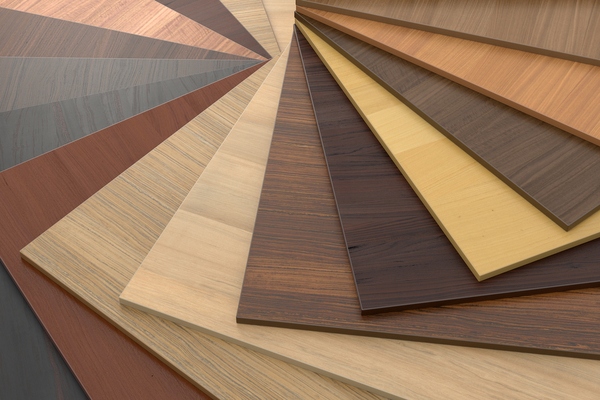

The market offers a diverse range of lamination PVC panels tailored to different design and functional needs. These variations can be broadly categorized based on:

-

Surface Finish: Options range from glossy and matte finishes to textured surfaces that mimic natural materials like wood or stone.

-

Thickness: Panels come in different thicknesses to suit various applications—from thin panels for decorative purposes to thicker variants designed for higher durability.

-

Color and Design Options: A wide array of colors and patterns allows designers to achieve the desired aesthetic, whether it’s a bold statement wall or a subtle, elegant ceiling.

-

Specialized Coatings: Some panels feature additional coatings for enhanced fire resistance, UV stability, or improved water repellence, making them suitable for specialized applications.

Primary Uses

Lamination PVC panels are incredibly versatile and are used in a variety of settings. Here’s a closer look at their primary applications:

Interior Decoration

In interior design, aesthetics and functionality go hand in hand. Lamination PVC panels provide an innovative solution for creating visually appealing spaces without compromising on durability.

-

Wall Cladding: These panels can be used to cover walls, providing a modern, sleek look. Their wide range of textures and colors enables designers to achieve unique finishes that enhance the overall ambience.

-

Ceiling Applications: PVC panels are also ideal for ceilings, offering a lightweight yet robust alternative to traditional materials. Their water-resistant properties help prevent issues such as mold or moisture damage.

-

Accent Features: Beyond standard installations, these panels are perfect for accent walls, custom installations, or even creating decorative features like patterned designs and geometric layouts.

Commercial Spaces

Commercial settings demand materials that are both stylish and resilient. Lamination PVC panels meet these requirements, making them a go-to choice in various business environments.

-

Retail and Hospitality: In retail stores, hotels, and restaurants, PVC panels enhance visual appeal while providing a durable surface that can withstand high traffic and frequent cleaning.

-

Offices: Modern offices benefit from the panels’ sleek design and low maintenance, creating professional and aesthetically pleasing work environments.

-

Signage and Displays: Their smooth finish and customizable design also make them suitable for creating effective advertising displays, signage, and promotional installations in commercial areas.

Outdoors (If Applicable)

While traditionally used indoors, some specialized lamination PVC panels are designed for outdoor applications, thanks to enhanced weather-resistant coatings.

-

Exterior Cladding: In certain cases, these panels are used as cladding for exterior walls, facades, or sunshades, offering durability against harsh weather conditions.

-

Balcony and Patio Enhancements: They can also be applied to outdoor spaces like balconies and patios, providing a stylish and maintenance-free alternative to traditional outdoor materials.

Material Advantages

Lamination PVC panels offer several distinct advantages that contribute to their popularity:

-

Durability and Stability: Engineered to resist impacts, scratches, and chemical corrosion, these panels maintain their appearance and functionality even in high-traffic or demanding environments.

-

Moisture and Humidity Resistance: Their waterproof properties make them an excellent choice for bathrooms, kitchens, and other areas prone to moisture.

-

Lightweight and Easy to Install: Compared to traditional materials like wood or metal, PVC panels are lightweight and easier to handle, which simplifies both installation and future modifications.

-

Environmental Considerations: Many lamination PVC panels are manufactured with eco-friendly processes. They are non-toxic, and some products are fully recyclable, aligning with green building practices.

-

Cost-Effective: Offering a balance between performance and price, these panels provide a cost-effective alternative to many natural and synthetic materials without sacrificing quality.

Maintenance Guidelines

One of the most attractive features of lamination PVC panels is their low maintenance requirements. Here are some practical guidelines to keep your panels looking and performing their best:

-

Regular Cleaning: Wipe down the panels with a damp cloth and a mild detergent. Regular cleaning prevents dust and grime buildup, preserving both appearance and function.

-

Avoid Abrasive Cleaners: Use non-abrasive cleaning products and soft sponges to avoid scratching the surface or damaging the finish.

-

Routine Inspections: Periodically check for any loose edges or signs of wear, especially in high-moisture areas. Address any minor issues promptly to prevent larger problems.

-

Professional Maintenance: For large commercial installations, consider scheduled maintenance checks by professionals to ensure the panels remain in optimal condition over time.

Conclusion

Lamination PVC panels offer a versatile, durable, and aesthetically pleasing solution for a wide range of applications. Whether used for interior decoration, in commercial settings, or even in specific outdoor applications, they combine the best of modern design and advanced engineering. With benefits such as ease of installation, low maintenance, and environmental friendliness, these panels are an excellent choice for anyone looking to enhance their space with a modern touch.

By understanding the types available, their primary uses, and the material advantages, homeowners, designers, and contractors can make informed decisions when selecting materials for their next project. Embrace the innovation of lamination PVC panels and transform your space into a modern, stylish, and sustainable environment.

Know more at:

What Are the Advantages of PVC Laminate Sheets?

What Is the Process of Lamination for PVC?

Post time: Feb-28-2025