In the realm of interior design and architecture, the advent of PVC wall panels has heralded a new era of versatility and aesthetic appeal. These panels, crafted through a meticulous manufacturing process, have become synonymous with innovation and modernity in interior embellishment. In this exploration, we unravel the intricate artistry behind PVC wall panel production, shedding light on the technology and craftsmanship that converge to create these transformative elements.

Prelude to Precision: Material Selection

At the heart of PVC wall panel manufacturing lies the careful selection of raw materials. Polyvinyl chloride, the primary component, undergoes rigorous quality assessment to ensure optimal performance and durability. Manufacturers meticulously source PVC resin, stabilizers, plasticizers, and additives, striking a delicate balance between structural integrity and aesthetic versatility. The quality of these materials forms the foundation upon which the entire production process rests, setting the stage for excellence in craftsmanship.

Formulation and Compounding: Engineering Innovation

The journey from raw materials to finished PVC wall panels begins with formulation and compounding – a process that exemplifies engineering ingenuity. Through precise calibration of mixing ratios and temperature controls, manufacturers achieve the ideal consistency and homogeneity of PVC compounds. This amalgamation of ingredients is akin to an alchemical process, where science and art converge to create a material that embodies both strength and flexibility. The formulation stage lays the groundwork for the subsequent manufacturing steps, ensuring uniformity and quality in the final product.

Extrusion Mastery: Shaping Possibilities

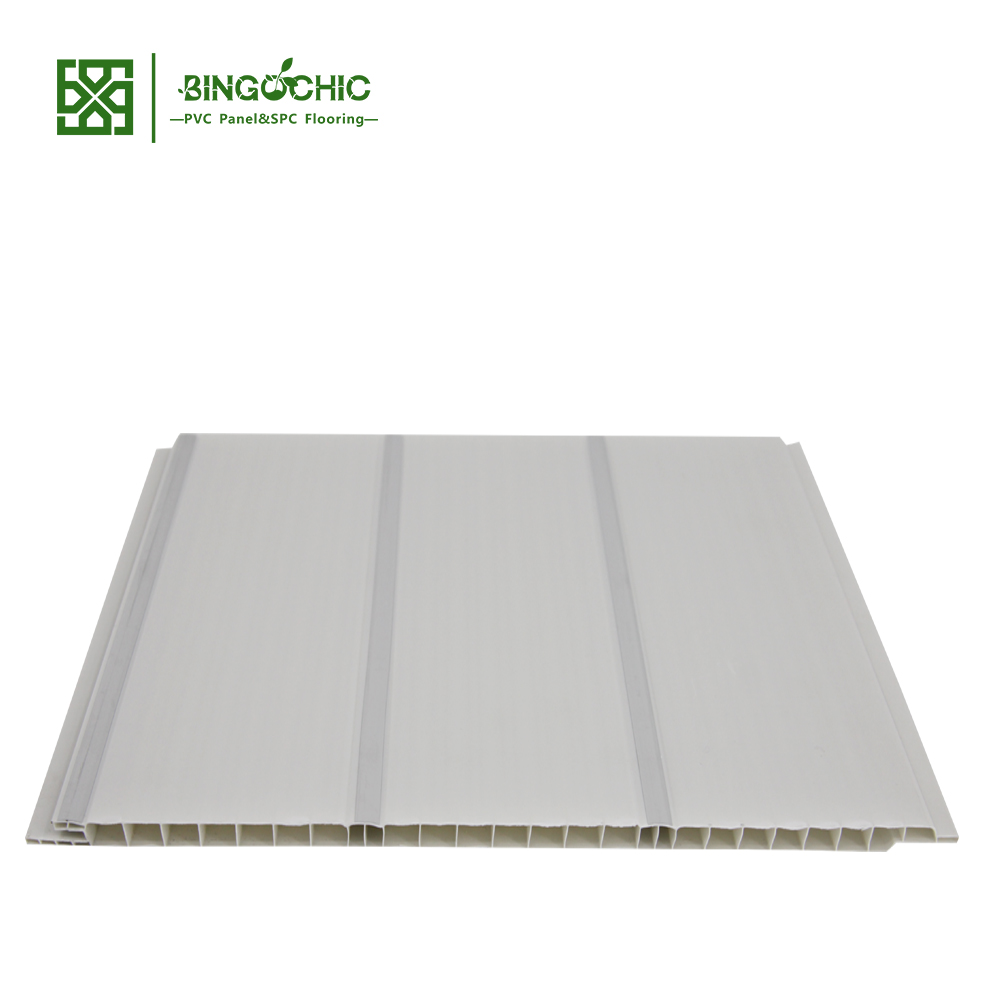

Extrusion emerges as the cornerstone of PVC wall panel manufacturing, offering a means to shape raw materials into intricate profiles and designs. The extrusion process begins with the feeding of PVC compounds into specialized machinery, where they undergo heating and compression within an extruder barrel. Under carefully controlled conditions, the molten PVC is forced through a die, assuming the desired shape and dimensions. From sleek minimalist profiles to ornate embossed patterns, extrusion technology empowers designers to realize their creative vision with precision and consistency.

Embossing and Surface Treatment: Artistic Flourishes

Embossing and surface treatment represent the artistic crescendo of PVC wall panels production, infusing surfaces with texture, depth, and character. Embossing rollers, engraved with intricate patterns, impart a tactile richness to the panels, simulating the look and feel of natural materials such as wood, stone, or metal. Meanwhile, surface treatments such as lamination or UV coating enhance durability and visual appeal, protecting the panels from wear and tear while accentuating their aesthetic allure. This marriage of craftsmanship and technology elevates PVC wall panels from mere functional elements to objets d’art, capable of transforming interior spaces with elegance and sophistication.

Quality Assurance: The Pursuit of Excellence

Throughout the manufacturing journey, quality assurance remains paramount, ensuring that every PVC wall panel meets exacting standards of performance and aesthetics. From comprehensive testing of raw materials to stringent inspections at every production stage, manufacturers leave no stone unturned in their quest for excellence. Dimensional accuracy, color consistency, and structural integrity are rigorously evaluated, with deviations from specifications addressed promptly to uphold the integrity of the final product. By prioritizing quality at every step, manufacturers instill confidence in consumers, establishing PVC wall panels as a benchmark of reliability and craftsmanship in the world of interior design.

Conclusion: Crafting the Canvas of Creativity

In the tapestry of interior design, PVC wall panels emerge as a canvas of creativity, shaped by the artistry and precision of the manufacturing process. From the selection of premium materials to the meticulous execution of extrusion and embossing, every stage of production embodies a commitment to excellence and innovation. As architects, designers, and homeowners embrace the transformative potential of PVC wall panels, they embark on a journey of aesthetic exploration and spatial reinvention. With craftsmanship as its compass and technology as its guide, the artistry behind PVC wall panel manufacturing continues to redefine the boundaries of interior embellishment, inviting us to reimagine the spaces we inhabit with ingenuity and style.

Post time: Apr-24-2024