Introduction to PVC Board Lamination

PVC board lamination involves the application of a protective or decorative layer onto PVC sheets to enhance their visual appeal and durability. This process is commonly used in various industries to improve the overall quality and functionality of PVC materials.

Properties of PVC Board

PVC board is known for its exceptional properties, including high durability, water resistance, and versatility. These characteristics make PVC a popular choice for a wide range of applications, from construction to signage.

Lamination Process for PVC Board

The lamination process for PVC board typically involves applying a laminate material onto the surface of the board using heat, pressure, or adhesives. This process helps to enhance the strength and aesthetics of the PVC material.

Suitability of PVC Board for Lamination

Due to its smooth surface and compatibility with various laminates, PVC board is well-suited for lamination. The material’s composition and texture make it a suitable candidate for enhancing through lamination.

Benefits of Laminating PVC Board

Laminating PVC board offers numerous benefits, including improved surface finish, increased durability, and enhanced resistance to scratches and stains. The lamination process can also add decorative elements to the PVC material.

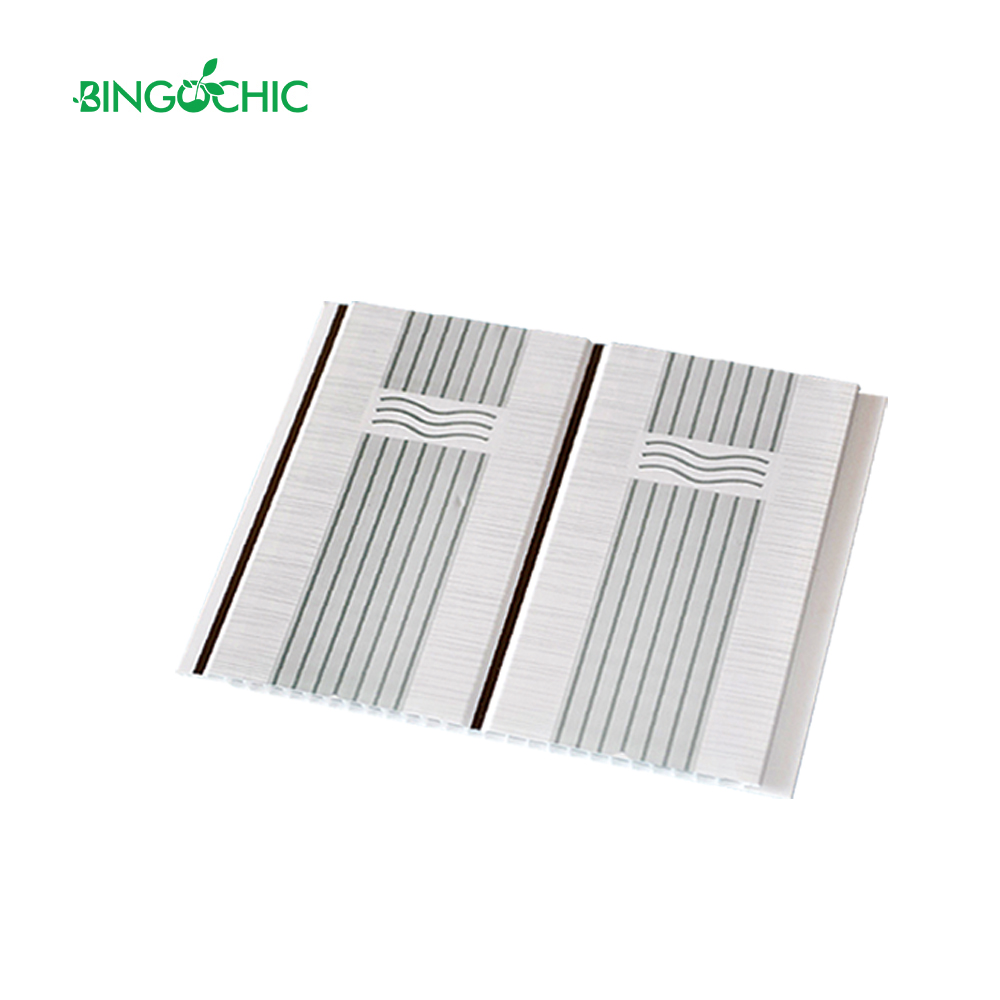

Types of Laminates for PVC Board

There are different types of laminates that can be used on PVC board, such as decorative laminates for aesthetic purposes, protective laminates for durability, and adhesive films for specific applications. Each type offers unique benefits for enhancing PVC board.

Lamination Techniques for PVC Board

Common lamination techniques for PVC board include heat lamination, pressure-sensitive lamination, and cold lamination. These techniques ensure proper adhesion of the laminate to the PVC surface, resulting in a durable and visually appealing finish.

Applications of Laminated PVC Board

Laminated PVC board finds diverse applications in industries such as signage for advertising displays, construction for interior finishes, furniture for decorative elements, and interior design for aesthetic enhancements. The versatility of laminated PVC board makes it a valuable material in various fields.

Considerations for Laminating PVC Board

Key considerations when laminating PVC board include proper surface preparation to ensure adhesion, selection of suitable adhesives for compatibility, and post-lamination care to maintain the quality of the finished product. Attention to these details is crucial for achieving optimal lamination results.

Conclusion

In conclusion, laminating PVC board offers a multitude of advantages in terms of aesthetics and functionality. By understanding the lamination process, the benefits it provides, and the considerations involved, one can effectively enhance the appearance and performance of PVC-based products across different industries.

Post time: Feb-29-2024