Made from a popular construction material and interior design element in any residential and commercial Askulae, PVC panels are one of the most popular construction materials. They apply in wall cladding, ceilings, and partitioning. One significant factor to be considered in choosing a building material, however, is its fire resistance properties. This paper comprehensively discusses the fire-resistance qualities of PVC panels through analyses of combustibility, flame retardants, evolving fire rating standards, smoke and toxicity tenets, and best practices in use for safety.

What Are PVC Panels?

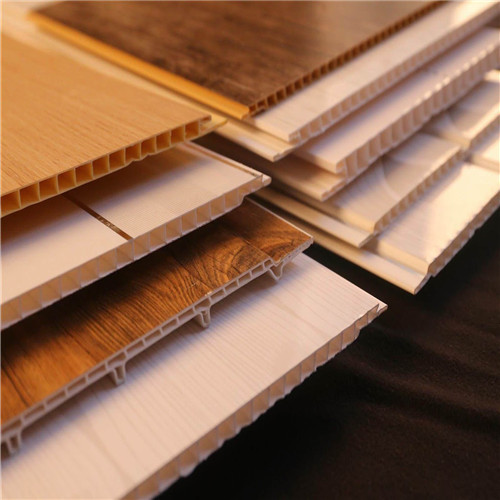

PVC panels are a blend of plastic variations developed by linking vinyl chloride monomers. Its lightweight, easy-to-install, and moisture resistance make it appropriate for many uses, ranging from very fine texture to colors and design. PVC panels can imitate the style of stone, wood, and other materials similar to those without problems associated with their maintenance. This makes the panels appropriate for use in bathrooms, kitchens, and other damp environments.

How Do PVC Panels React to Fire?

By itself, PVC is essentially a combustible material; it ignites and burns in the presence of adequate heat. However, compared with other plastics, its combustibility is relatively lower due to some resistance from chlorine contained in the polymer structure. Combusting PVC emits hydrogen chloride gas. Hydrogen chloride acts as a kind of flame retardant in the burning process, which slows down combustion. Thus, this attribute inherently renders PVC fire-resistant to a limited extent.

Although having some natural flame retardancy, regular PVC panels can burn and feed a flame. The time and quantity in which they do so depend on several factors, such as the size of the panels involved, the materials used in their construction, and prevailing weather conditions at the time of exposure to fire. It, therefore, means that one has to know that though PVC panels resist to some extent fire, this does not render them fireproof. They can still pose a great risk of fire if the matter is not properly dealt with.

Enhancing Fire Resistance with Additives

During their production process, producers often add flame retardancy additives to make PVC panels more fire-resistant. The flame retardants delay either the time of ignition or slow down a burning process once it has started. Flame retardant additives commonly used in PVC panels include:

Antimony trioxide: It is often combined with other flame-retardants to produce a layer of char on the PVC surface, which reduces the flow of flames. In the case of aluminum hydroxide, upon heating, it starts releasing water vapors that cool the material and dilute the flammable gases in it, hence serving as a retardant.

Phosphates: Organic phosphate compounds can increase the char-layer formation and perform as plasticizers, which makes the PVC more flexible and, hence, less likely to ignite.

Some of these additives make some difference, and how much impact they will have on the general fire resistance of PVC panels depends on the final formulation made by the manufacturer. Fire ratings for PVC panels thus have to be checked before installation, so that they adhere to set safety standards.

Smoke and Toxicity Concerns

While flame retardant additives can enhance the fire-resistance properties of PVC panels, the combustion of PVC nonetheless gives rise to significant concerns over smoke and toxicity. Burning PVC emits hydrogen chloride gas, which can mix with moisture in the air to form hydrochloric acid. This is a very corrosive acid gas formed during combustion that can cause serious respiratory problems if inhaled.

Apart from hydrogen chloride, other toxic gases produced from PVC combustion include dioxins and furans, largely when they burn away in low-oxygen conditions. Such are highly hazardous compounds to human health and the ecosystems that form part of it and make fires formed on PVC materials quite a bother to deal with. It is for such toxic gases that may be liberated to revamp a fire safety mechanism whenever PVC panels are involved in building construction.

Safe Use of PVC Panels

Noting the potential fire risks associated with PVC panels, appropriate steps, and applications should be considered with caution. The best practices for using PVC in construction concerning safety are:

Use Fully Certified Products: Use only those PVC panels that go through examinations and tests for fire resistance according to recognized standards. Flammable materials like PVC should not be left close to any heating equipment or other open flames.

Proper Installation: The installation instructions given by the manufacturer should be followed as appropriate installation contributes to upholding the fire-resistant properties of these panels. However, improper installation may considerably lower the efficiency of flame retardants and increase the possibility of fires in the long run.

Fire Safety Systems: Comprehensive fire safety systems should be installed at places where the PVC panels are used intensively. Smoke detectors, fire alarms, and sprinkler systems should be fitted so that the development of any fire can be detected at a fast pace and proper action may be taken against it.

Regular Inspections: Be constantly on the lookout and maintain to ensure that PVC panels remain in good condition, with all their properties—fire-resistant—intact. Any damage or wear must be addressed promptly to help prevent potential fire hazards.

Limit High-Risk Applications: Avoid using PVC panels in applications where the risk of exposure will increase the chances of a potential fire outbreak or where the consequences of a break-out are very severe. In such high-risk applications, other materials with more satisfactory characteristics of fire performance must be chosen.

Inform Occupants: The occupants of the building should be well informed on procedures regarding fire safety and the potential risks associated with PVC panels, that evacuation plans are in order, and the occupants know what procedures to take if the situation of a fire occurs.

Conclusion

The PVC panel brings a lot of benefits in terms of versatility, durability, and esthetics; the result is that it finds a rather common application in most construction and design projects. Naturally, they are not inherently fireproof, although incorporating flame retardant additives and proper installation practices do enhance their fire resistance. Understanding the PCV panel characteristics regarding fire resistance and following safety guidelines will help safeguard their application in nearly all usages.

You can reap all the benefits that PVC panels have in store for you through certified products, following the safety prescriptions, and including all kinds of fire safety measures. Be aware and proactive on fire safety to safeguard your property and its occupants.

Know more at:

Are PVC Panels Waterproof?

Can You Put PVC Panels in a Shower?

How Long Do PVC Panels Last?

Post time: Jul-29-2024