Where interior design, signage, and other construction projects are concerned, two of the most common materials providers use are acrylic and PVC panels. Each of these materials has special advantages and features that suit it only for particular kinds of jobs. This article attempts to throw light on the properties, benefits, and possible shortcomings of both, so you may make a proper choice based on your specific needs.

Acrylic Panels

Composition and Characteristics

One example of such a plastic is acrylic, also known as PMMA, which is an optically transparent thermoplastic that, further often enhanced with shatter-resistant qualities over the more heavy and fragile glass. Very often, acrylic panels are defined for durability, clarity, and multipurpose use. They come in a wide color and finish range, such as clear, frosted, and colored, making them quite suitable for varied applications.

Advantages

Optical Clarity

Acrylic panels have excellent clarity and transparency; as such, they can be used in display cases, window panes, and screens where clarity of vision is necessary. In terms of light transmission, they stand almost equal to glass and give crystal-clear vision.

Lightweight

Compared to glass, acrylic is very light. It is easier to handle and install. This property also reduces transportation costs and the structural support needed for installation.

Resistance to Shock

Not as tough as polycarbonate, but amongst the other plastics available, it takes better than glass in impact resistance. This property results in a lower extent of shattering. Hence it is a safe material where shattering glass may be hazardous.

Resistant to UV

Acrylic panels exhibit a very negligible response to UV light, and hence it does not turn yellow after some time due to degradation. Thus, they can function perfectly under the sun.

Thermoformable

Acrylic is easily bendable and moldable upon heating. This enables interesting, customer-individual design solutions. This attribute has made acrylic quite popular in artistic and architectural uses.

Disadvantages:

Scratches Easily

Acrylic is a scratch-prone material. Scratches reduce not only the appeal but also optical clarity. Special coatings can be applied for better scratch resistance, however at an additional cost.

Lower Resistance to Chemicals

Acrylic tends to react to certain chemicals, which can be a cause of damage. Keep them away from cleaning products and solvents like acetone.

Cost: Usually, acrylic panels are more expensive compared to other plastic alternatives. However, their long-term durability and aesthetic appeal can justify the initial investment.

PVC Panels

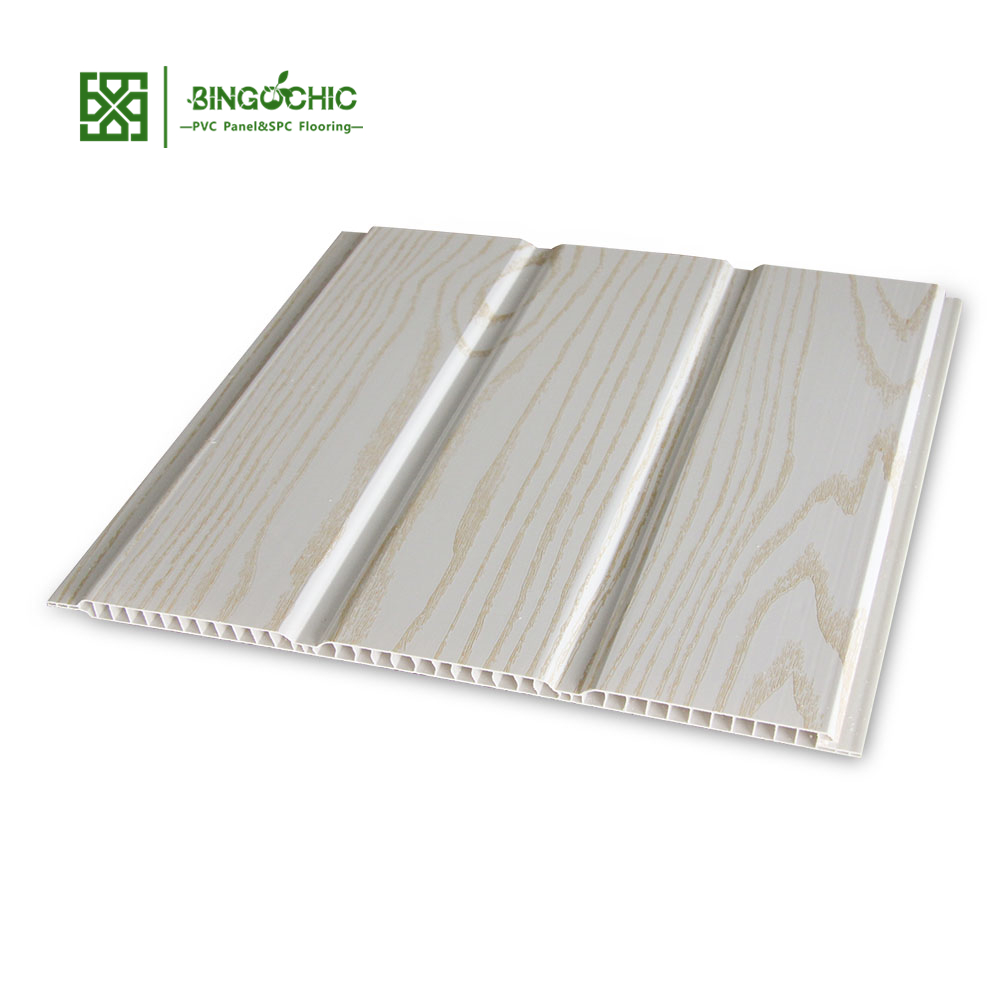

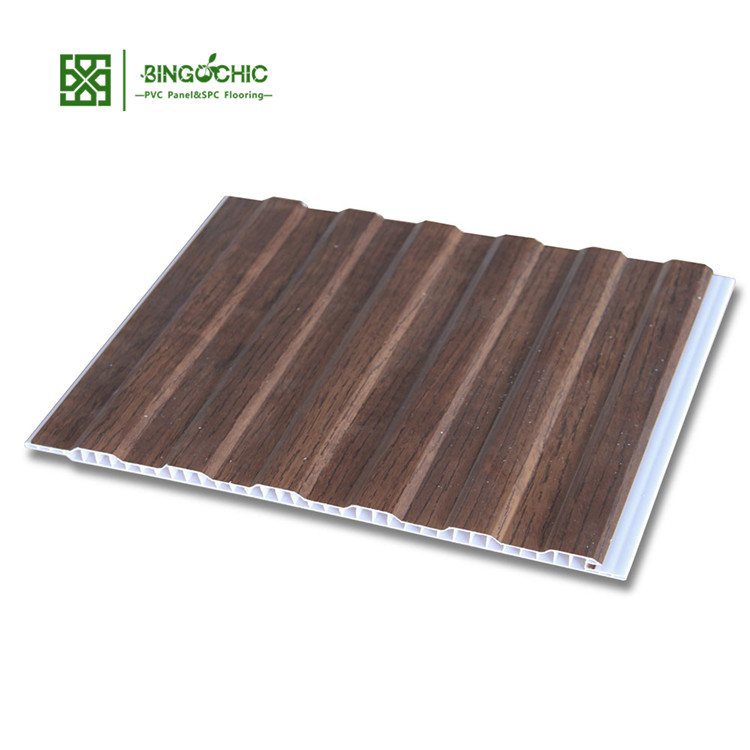

Composition and Properties

One of the synthetic plastic polymers, which is largely applied in construction and building materials, is PVC. In terms of their price, the PVC panels are strong, easy to install, and cost-effective. They come in forms like solid, foam, or even layered structures, all for specific applications.

Advantages

Durability

PVC panels are very highly resistant; they bear every rough environmental condition, thus making them suitable for both interior and exterior designs. They do not corrode, rot, or get destroyed by insects, and this offers quality and life-long services.

Waterproof

Not only does PVC have a self-nature of resistance toward water, but it’s also fitting for places with excess moisture, say, the bathroom and kitchen environments. This feature enables its use as cladding in marine environments.

Chemical Resistance

Since the list of chemicals that PVC panels are resistant to is long, they are, therefore, quite suitable for industrial environments. They won’t suffer significant degradation from contact with acids, alkalis, and salts.

Easy Maintenance

The PVC is easy to clean and maintain; it’s just wipe-down to renew. It doesn’t require painting or sealing, thus reducing the effort in long-term maintenance.

Cost-Effective

Generally, PVC panels are cheaper compared to acrylic and therefore very suitable for people under a tight budget. The cost of the materials does not compromise functional performance; hence, this makes them suitable for most cost-sensitive applications.

Disadvantages

Appearance

PVC panels lack the high optical clarity that acrylic does, and this can limit them to working in applications involving absolute transparency. It is aesthetically not pleasing like acrylic, which has a shiny finish.

Thermal Expansion

Since PVC has the property of thermal expansion and contraction, it would warp in case the installation is faulty. Proper spacing and methods of installation, however, reduce this effect. Brittleness: PVC is brittle at very low temperatures and thus is very easily cracked. It hereby has limited uses in very low-temperature environments.

Applications

Acrylic Panels

Signage and Display

The clarity and durability of acrylic make it outstanding for such applications as illuminated signs, retail displays, and exhibition stands.

Windows and Skylights

Its lightweight mass, with excellent resistance to UV, makes this compound an excellent substitute for glass in windows, skylights, and greenhouses.

Aquariums

Much is also applied for aquariums, as this plastic produces immense strength with clarity that serves well to view the aquatic life.

Furniture

In modern furniture designs, acrylic has been applied in making chairs, tables, and shelving that provide a sleek, modern look.

Protective Barriers and Shields

Acrylic barriers find the most predominant application across offices, retail environments, and public spaces aimed at protection with a view.

PVC Panels

Wall Cladding and Partitions

Interior wall cladding undertaken by PVC panels is explicitly applied as an easy and self-explanatory method to install and maintain in residential and commercial areas.

PVC Ceiling Panels

They sometimes have to ensure the delivery of moisture-resistant and low-maintenance applications in kitchens, bathrooms, and basements.

Bathroom and Kitchen Wall Protection

Aspects of water resistance make PVC panels befitting for wet areas, thus not allowing mold and mildew growth.

Industrial Applications

In factories, laboratories, and so on, PVC panels are applied when high chemical resistance and durability are required in-service conditions.

Signage (in cases where transparency is not necessary)

Very often, PVC is used in non-illuminated signs that include outdoor advertisement types, wayfinding signs, and boards providing information.

Environmental Considerations

Acrylic

Now, from the point of ground color, acrylic production makes use of petroleum-based materials; hence, it is not exactly very environmentally friendly. On the brighter side, though, acrylic can be recycled, and lots of manufacturers have in place acrylic recycling programs. Besides, over time, acrylic products’ durability and long lifespan help in reducing their environmental imprint.

PVC

It has also been criticized for its environmental implications while being produced and also while disposed of. The production process involves chlorine, and some chemicals released are quite harmful. In recent years, however, the innovation of manufacturing processes has minimized the effect to some extent. PVC is recyclable, and recycled PVC is being used vastly in many sectors.

Conclusion

The choice between acrylic and PVC panels mainly relies on the requirements of your project. Applications requiring high optical clarity and impact resistance combined link with acrylic panels. On the other hand, PVC panels find their applications in durability, water resistance, and at times lower-budget requirements. Knowing what properties and benefits all of them have as single elements, along with the kind of relations they share with the environment, is going to let you choose the correct one for what your specifications are. Both materials offer a great deal centering on versatility and functionality related to building and design today.

Post time: Jul-09-2024